- Contact Us

- Microtec Factory Address: GuoYang Factory, #83 Hengdong Road, Dongkeng Town, Dongguan City, 523448, China Contact Now

- High Click

- Latest News

-

Reimagine Tumbler Personalization with Microtec’s MP-170 Heat Press

The Fully Auto Tumbler Mug Heat Press MP-170 is the ultimate machine for customizing 20-30oz tumblers. With fully automated operation, precision digital controls, and even heat distribution, it ensures vibrant, long-lasting designs. Ideal for print shops, promotional product companies, and small businesses, the MP-170 streamlines tumbler printing with speed, efficiency, and professional results. Enhance your customization capabilities with this durable, user-friendly heat press.Next-Level Heat Transfer -- the Mighty Auto Heat Press

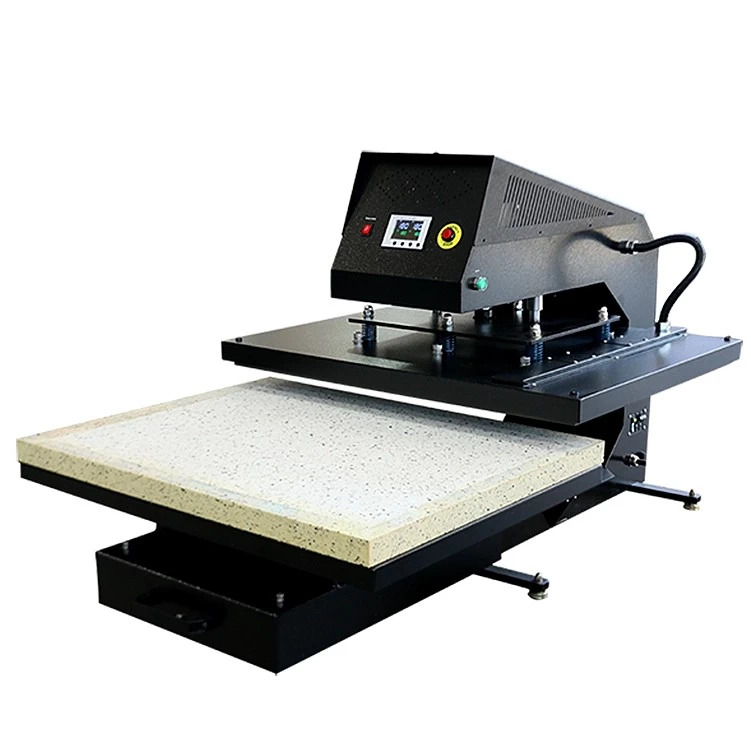

The Mighty Auto Heat Press is a high-performance heat transfer machine featuring a large touchscreen panel, automatic pressure adjustment, and a spacious 40x50 cm pressing area. Perfect for print shops, small businesses, and manufacturers, this durable and efficient press ensures flawless results on a variety of materials, making it ideal for scaling operations in the growing customization market.MAX-CAP2 Dual-Heating Cap Heat Press: The Ultimate Machine for Professional Cap Customization

The MAX-CAP2 Dual-Heating Cap Heat Press is a professional-grade machine designed specifically for cap and hat customization. Featuring dual-heating plates for even heat distribution, this innovative heat press ensures flawless transfer results on a variety of headwear. Its adjustable temperature, time, and pressure settings make it versatile for handling vinyl, sublimation, and screen-printed transfers. Built with a durable frame, ergonomic design, and enhanced safety features, the MAX-CAP2 is ideal for businesses in the fashion, promotional, and sports industries. Compact and reliable, it’s the perfect tool for creating custom caps efficiently and professionally.Maximize Efficiency and Quality with the RHP-15MS-V2 Dual-Sided Heat Transfer Machine

The RHP-15MS-V2 Dual-Sided Heat Transfer Machine is a revolutionary solution designed to enhance efficiency and productivity in heat transfer applications. Equipped with dual heating plates, it enables simultaneous double-sided transfers, ensuring consistent and high-quality results. Ideal for industries such as textiles, custom gifts, and e-commerce, this machine significantly reduces production time, making it perfect for bulk orders and high-demand environments. Its ergonomic design, strong pressure capability, and versatile applications—ranging from apparel to personalized items—make it a reliable choice for businesses seeking to streamline operations while delivering professional-grade results. Built for durability and efficiency, the RHP-15MS-V2 sets a new standard for heat transfer technology.Advanced Safety Features for a Safer and More Efficient Heat Pressing Experience-XPDS - 20 Heat Transfer Machine

The XPDS-20 Heat Transfer Machine is a high-performance, dual-station heat press designed with advanced safety features to ensure both user protection and operational efficiency. Equipped with the Pinch-Guard Safety System, it automatically detects obstructions, halting and raising the heating plate to prevent injuries. The Limit Switch Function ensures precise plate alignment during dual-station use, while the Emergency Stop Function provides quick halting in case of malfunctions, raising the platen to avoid further damage. Ideal for high-volume printing, custom apparel, and promotional products, the XPDS-20 combines safety, precision, and efficiency to meet the growing demands of the heat press market.A Perfect Solution for Easy and Safe Garment Transfers-Microtec UX series Heat Press Machines

The Microtec UX-15 and UX-20 Heat Press Machines are designed to meet the growing demand for affordable, high-quality heat transfer solutions. Featuring a wide opening angle, these manual clamshell heat presses make it easier and safer to load garments, improving efficiency and reducing the risk of burns or accidents. Ideal for small to medium-sized businesses and hobbyists, they offer easy garment placement, precise pressure control, and even heat distribution with a Teflon-coated platen. With a digital controller for accurate settings, these heat presses are perfect for custom t-shirt printing, vinyl transfers, and sublimation, providing businesses with a cost-effective way to achieve professional results.Revolutionize Sublimation Printing with the Microtec XSTM-48P: The Industrial Solution with Replaceable Heating Tube

For industrial pneumatic large-format sublimation machines, a replaceable heating tube is a forward-thinking innovation that ensures uninterrupted operation, lowers long-term costs, and enhances user convenience. Businesses can maximize productivity and quality while enjoying a higher level of customization and reliability.Boost Productivity with Microtec’s MTX-54 Rotary Calendar Heat Press Featuring Automatic Blanket Alignment

Microtec proudly presents the MTX-54 Rotary Calendar Heat Press, a cutting-edge solution for sublimation printing and textile transfer applications. This model is designed for high-volume, precision-focused businesses, offering industry-leading features such as an automatic blanket alignment mechanism. Engineered for efficiency, reliability, and superior results, the MTX-54 is a must-have for businesses aiming to enhance production quality and throughput.Transform Your Printing Efficiency with Microtec’s APHD-32S Dual-Heating Heat Transfer Machine

The Microtec APHD-32S Double Sided Sublimation Heat Press is an industrial grade heavy duty heat press for mass production. The high pressure of the large pneumatic heat press is ideal for sublimation metal printing.What’s a Metal Print and How to Make Metal Prints? Why Microtec's APHD-43P is Perfect for This Application?

Microtec APHD Sublimation heat press machine is Industrial grade heavy duty heat press for large-scale productions. Large pneumatic heat press with high pressure, perfect for sublimation metal prints.The Future of Laser Positioning Systems in Garment Printing: How Microtec Enhances Precision and Efficiency

Enhance your T-shirt printing precision with our advanced T-shirt Laser Alignment System. Designed for professional heat press machines, our system ensures perfect alignment and accuracy for all your heat transfer applications. Reduce errors, save time, and improve the quality of your prints. Discover how our laser alignment tool can transform your printing process today.What's Print on Demand? How Microtec's Automatic Mug Wrap Can Help You Scale Faster

The MWM-10 is designed with state-of-the-art automation technology, ensuring consistent and flawless wrapping of your mug designs. Its precision mechanics ensure that every wrap adheres perfectly, leaving no room for errors or imperfections. Whether you're creating a single prototype or mass-producing custom mugs, the MWM-10 delivers exceptional results every time and elevate your mug customization game to new heights.Why Dual Station Automatic Heat Press?

A dual station automatic heat press machine allows for simultaneous pressing of two items, significantly reducing the time needed for each heat transfer job. With its advanced pneumatic technology, this machine ensures consistent pressure and temperature distribution, resulting in high-quality prints every time.Automatic Feeding Device for Your Lanyard Printing Project

By integrating the Electric Lanyard/Ribbon Feeding Device Heat Press Machine, you'll enhance productivity, reduce downtime, and achieve a higher level of operational efficiency. This combination is perfect for businesses looking to scale up their production without compromising on quality.Maximize Heat Press Efficiency with the Revolutionary Splitter Stand

Microtec splitter stand is a valuable addition to any garment printing setup, particularly for those using Microtec SHP series heat press machines. By preventing double compression, eliminating ink migration, and streamlining garment handling, it significantly enhances the efficiency and quality of your heat press operations. Invest in a splitter stand today and experience the difference it can make in your garment printing business.Tumbler Heat Press - Best Press for Sublimation Tumblers | Microtec

Explore Microtec's top-quality tumbler heat press machines, ideal for sublimation tumblers. Learn about settings, temperature, and more. Visit www.heatpress.cn.High-Performance APD Series Pneumatic Heat Press Machine for Professional Use | Microtec

Explore the APD Series Fully Automatic Pneumatic High-Pressure Heat Press by Microtec. Ideal for professional heat transfer on T-shirts, garments, and fabrics. Available in 16x20 and 16x24 sizes, offering consistent high pressure, precise temperature control, and user-friendly operation. Enhance your printing efficiency and quality with Microtec's durable and reliable heat press machine.Discover Microtec X-Series – A Breakthrough in Heat Transfer Printing Technology

Microtec X-Series represents the pinnacle of innovation in heat transfer printing technology. Our upgraded electric motor seamlessly combines automation, user-friendly controls, and versatile garment handling, revolutionizing the printing process. Featuring a sleek 6-inch touchscreen interface and a specialized clothing compartment, achieving professional-grade results has never been easier.

- Follow us

- Subscribe

-

Get email updates on new products

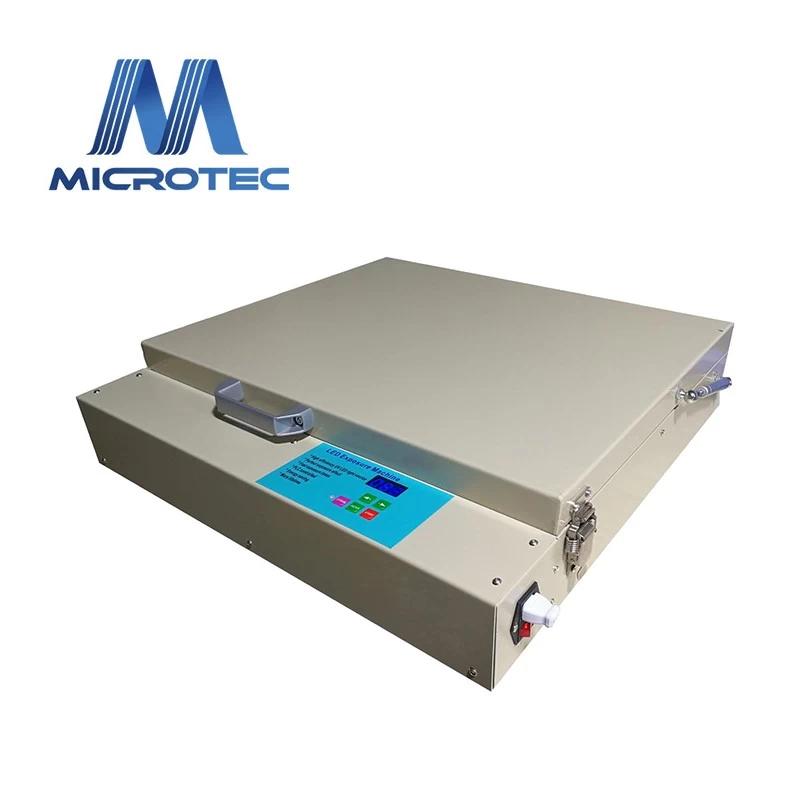

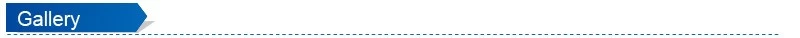

High Efficiency UV LED Exposure Unit

- Model No.: MT-EP03

- Max.Exposing Area: 520*610mm

- Voltage (Single Phase ): 220V or 110V

- Time Control: 0-999s

- Power of Lamps: 80W (8 10w UV LED-line)

- Packing Size: In One Carton(750*680*200mm)

- Weight: 30kg

This machine adopts intelligent digital control. The exposure time is more accurate, meanwhile,with the design of small volume,compact structure, stable light source, ability of working normal with low voltage, and good correspondency between the wavelength and the photosensitive material,making the texts and images clear and increasing the print rate.

This machine adopts intelligent digital control. The exposure time is more accurate, meanwhile,with the design of small volume,compact structure, stable light source, ability of working normal with low voltage, and good correspondency between the wavelength and the photosensitive material,making the texts and images clear and increasing the print rate.

High efficiency and energy saving are the most prominent features of LED printers. The actual trial printing speed is several times than other light sources.

*Adopting high efficiency UV LED light source,which save 50% electricity than ordinary model

*PLC controlled panel, very easy to operate

*Automatic memory function for working as original seting next time

*Perfect exposure effect because of LED light

*Fast exposure time,about 40-70 seconds

*Energy saving and environment friendly

*Stable exposure quality,more lifetime

*Durable and beautiful with steel coat

*Outside connecting power plug, safety and convenience

*Easy to transport,LED light is not fragile in delivery

*PLC controlled panel, very easy to operate

*Automatic memory function for working as original seting next time

*Perfect exposure effect because of LED light

*Fast exposure time,about 40-70 seconds

*Energy saving and environment friendly

*Stable exposure quality,more lifetime

*Durable and beautiful with steel coat

*Outside connecting power plug, safety and convenience

*Easy to transport,LED light is not fragile in delivery

| Model No. | MT-EP03 |

| Max. Exposing Area | 520*610mm |

| Voltage (single phase ) | 220V or 110V |

| Time Control | 0-999s |

| Power of Lamps | 80W (8 10w UV LED-line) |

| Packing Size | In One Carton(750*680*200mm) |

| Weight | 30kg |

The LED exposure unit is used in the filed of plate-making such as pad plate, screen plate, hot stamper plate, resin plate. When you put the film onto the plate into UV LED exposure machine, start it, the emulsion on the plate will appear a unseen imagine. This is important process on all plate-making technology.

Microtec Technology Co., Ltd.

Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF